Design of Exterior: Styling

Design of Exterior: Styling

Summary

Automotive exterior design harmonizes aesthetic appeal with functional performance through balanced proportions (e.g., dash-to-axle ratios), premium Class-A surfaces (G2/G3 continuity for seamless light reflection), and iterative development from sketches to digital/clay modeling, while maintaining brand identity via signature grilles and lighting; it must also integrate aerodynamic efficiency (reducing drag via CFD/wind tunnel testing), comply with safety/regulatory standards (pedestrian protection, lighting), adhere to manufacturing constraints (stamping feasibility, assembly), and increasingly incorporate sustainable materials and modular designs for future mobility solutions.

Learning Objectives

Analyze the fundamental principles governing automotive exterior design and their impact on vehicle aesthetics and functionality.

Evaluate the relationship between design proportions, surface development, and consumer perception in automotive styling.

Apply surface modeling techniques and Class-A surface principles in automotive design development.

Synthesize brand identity elements with functional requirements to create cohesive exterior design solutions.

Critique the integration of aerodynamic considerations with aesthetic design objectives.

What Makes a Good Automotive Design?

An aesthetically successful vehicle design relies must have well-balanced proportions and premium surfaces.

Proportions

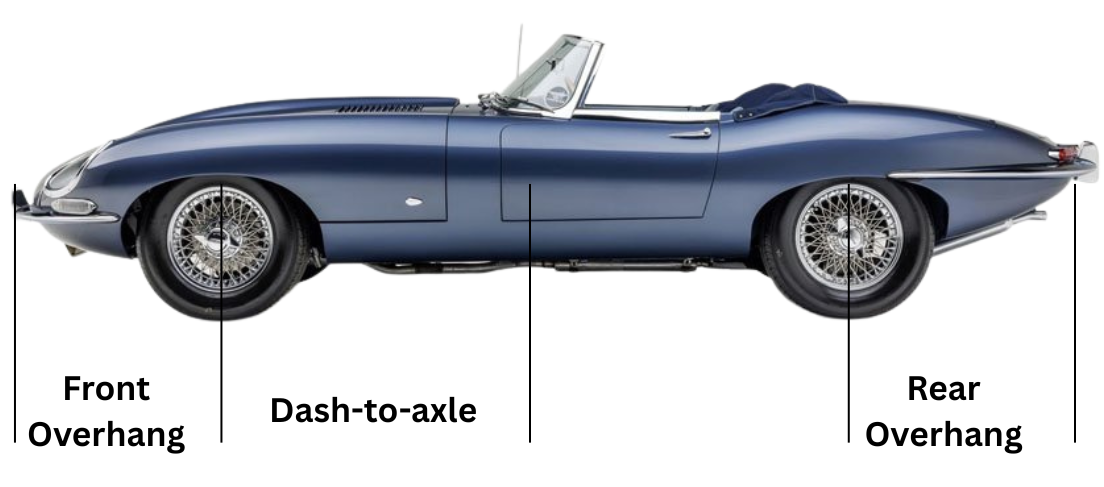

Vehicle proportions significantly influence consumer perception and brand positioning. The fundamental proportional relationships include: \[\[\begin{equation} \text{Dash-to-Axle Ratio}=\frac{\text{Distance from front axle to dashboard}}{\text{Wheelbase}} \end{equation}\]\]

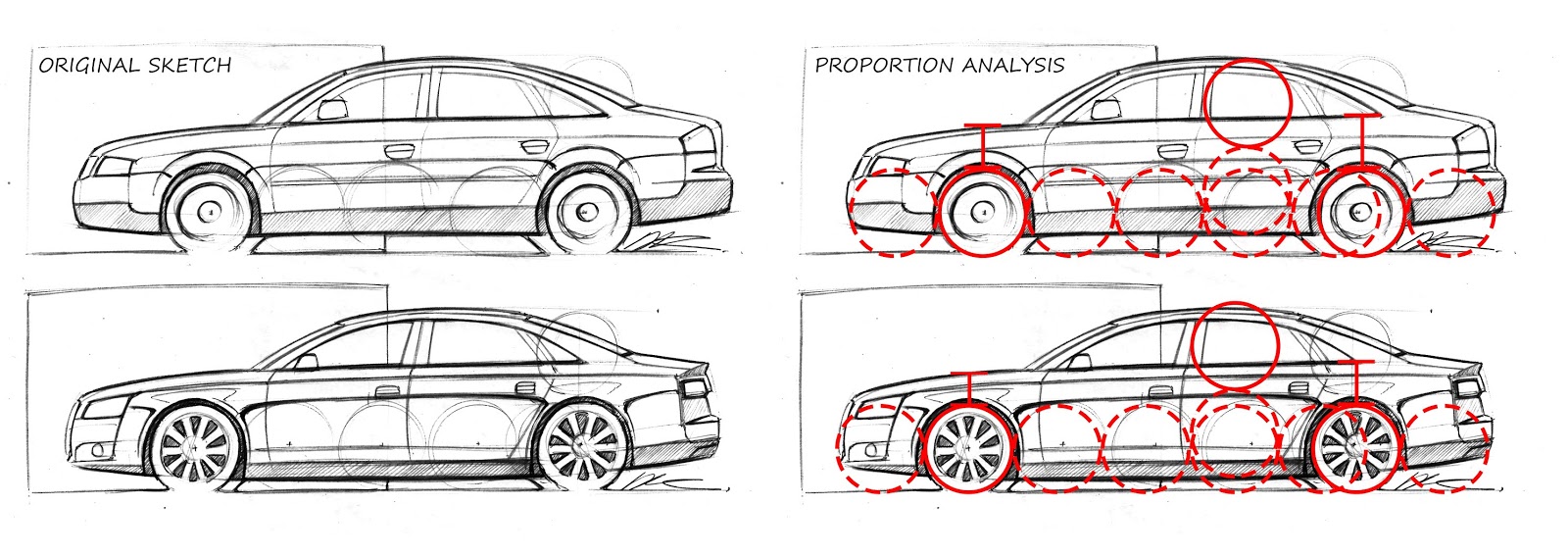

This ratio typically ranges from 0.42 to 0.48 for passenger vehicles, with lower values suggesting sportier characteristics (Choi and Chan 2007). Figures 1.1, 1.2 illustrate these critical dimensional relationships.

Classical automotive proportions showing the relationship between cabin, hood, and deck dimensions.

Classical automotive proportions showing the relationship between cabin, hood, and deck dimensions.  Proportional analysis showing dash-to-axle ratio variations across vehicle segments.

Proportional analysis showing dash-to-axle ratio variations across vehicle segments.

How is Brand Identity Reflected in Vehicle Design?

Visual Brand Language

Automotive brands develop distinctive visual languages that communicate their values and positioning. These visual elements must be consistently applied across all vehicle models while allowing for individual character expression (Karjalainen 2007).

Brand identity elements showing consistent grille design, lighting signatures, and proportions across model range.

Brand identity elements showing consistent grille design, lighting signatures, and proportions across model range.

Brand identity elements include:

Signature grille design : Distinctive front-end identity that serves as the brand’s face

Lighting signatures : Unique headlight and taillight patterns that enhance recognition

Proportional themes : Consistent dimensional relationships across vehicle segments

Surface treatment : Brand-specific surface language including highlight placement

Color palette : Strategic use of brand colors in design details and accents

Brand Evolution and Consistency

Successful automotive brands maintain visual consistency while evolving with contemporary trends. This balance requires strategic design management that honors heritage while embracing innovation (Person et al. 2008). The challenge lies in maintaining recognizability across diverse vehicle segments and global markets.

Brand evolution timeline showing design language development over decades.

Brand evolution timeline showing design language development over decades.

What are Other Factors to Consider?

Designing a vehicle’s exterior is a complex process that goes far beyond aesthetics. While visual appeal is crucial, several other factors must be carefully balanced to ensure the vehicle performs well, is safe, and meets regulatory and manufacturing requirements.

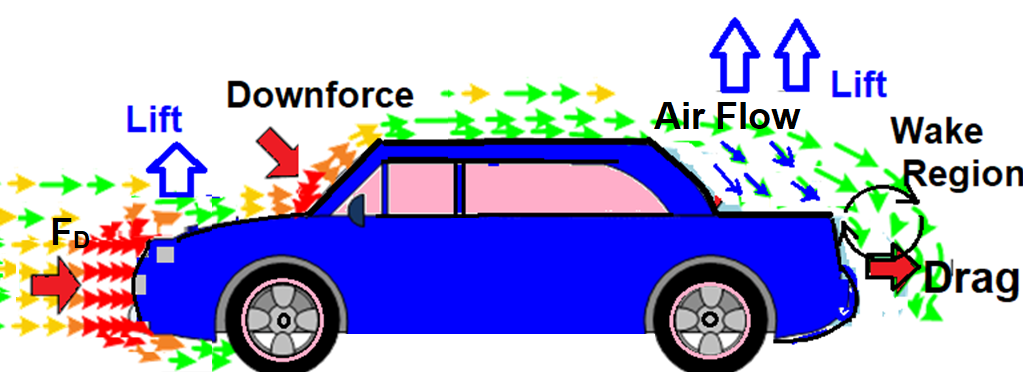

Aerodynamics

Aerodynamics plays a vital role in vehicle efficiency and performance. A well-designed exterior reduces drag, which:

Improves fuel efficiency or battery range (for EVs)

Enhances high-speed stability

Reduces wind noise

Designers use wind tunnel testing and computational fluid dynamics (CFD) to refine shapes, optimize airflow, and integrate features like spoilers, diffusers, and underbody panels. Figure 1.7 shows the effects of aerodynamic forces on a moving vehicle.

Aerodynamic effects.

Aerodynamic effects.

Design for Manufacturing (DFM)

DFM ensures that the vehicle can be produced efficiently and cost-effectively. This includes:

Simplifying shapes for easier stamping or molding

Reducing the number of parts and fasteners

Choosing materials compatible with existing production lines

Ensuring tolerances and fitment are achievable at scale

Regulatory and Safety Considerations

Vehicle exteriors must comply with a wide range of regulations, including:

Pedestrian safety: Front-end design must minimize injury in case of collision Figure 1.8.

Lighting and visibility: Placement and brightness of headlights, taillights, and indicators must meet legal standards

Crashworthiness: Structural integrity and crumple zones are influenced by exterior design

Environmental regulations: Materials and coatings must meet sustainability and recyclability standards

Regulatory considerations showing pedestrian safety zones and visibility requirements.

Regulatory considerations showing pedestrian safety zones and visibility requirements.

Ergonomics and User Experience

Exterior design affects the interior which is how the users interact with the vehicle:

Door handle placement and ease of access

Visibility from the driver’s seat (influenced by pillar design and window shapes)

Integration of sensors and cameras for ADAS (Advanced Driver Assistance Systems)

Sustainability and Material Innovation

Modern vehicle design increasingly incorporates sustainable practices:

Use of recycled or bio-based materials

Lightweight materials to reduce energy consumption

Modular components for easier repair and recycling

References

Choi, S. H., and A. M. M. Chan. 2007. “A Virtual Prototyping System for Rapid Product Development.” Computer-Aided Design 39 (5): 384–403. https://doi.org/10.1016/j.cad.2007.01.005.

Karjalainen, Toni-Matti. 2007. “It Looks Like a Toyota: Educational Approaches to Designing for Visual Brand Recognition.” International Journal of Design 1 (1): 67–81. http://www.ijdesign.org/index.php/IJDesign/article/view/44.

Person, Oscar, Jan Schoormans, Dirk Snelders, and Toni-Matti Karjalainen. 2008. “From Brand Identity to Product Form: A Design Process for Brand Consistency.” Design Studies 29 (5): 432–49.

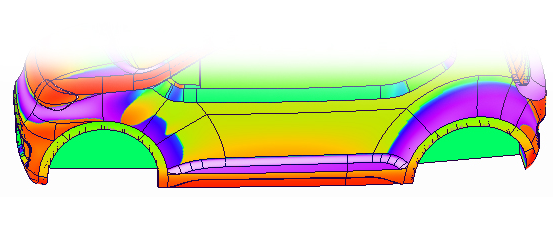

Class-A surface evaluation showing curvature analysis and highlight line quality.

Class-A surface evaluation showing curvature analysis and highlight line quality. Clay modeling process showing the progression from digital design to physical model.

Clay modeling process showing the progression from digital design to physical model.