The Automotive from Product Design Perspective

The Automotive from Product Design Perspective

Summary

Automotive product design follows a structured, systematic process, commencing with a thorough analysis of customer needs that are subsequently translated into specific, measurable technical and functional requirements. This multi-step framework, which guides engineers from initial conceptualization through detailed design, testing, and final production, critically balances customer desires with manufacturing realities and various regulatory constraints. Furthermore, modern automotive design is increasingly adopting circular economy principles, shifting away from a traditional “take-make-dispose” model to prioritize the entire product life cycle for enhanced sustainability, resource efficiency, and the generation of new economic opportunities through strategies like remanufacturing and material recovery.

Learning Objectives

Explain automotive engineering design principles and applications

Analyze the automotive design process from requirements to production

Convert customer needs into technical specifications

Balance customer demands, manufacturing limits, and regulations

Apply structured design methods to automotive challenges

Explain product life cycle impacts on automotive design

Apply circular economy principles for sustainability

Assess how design affects manufacturing, cost, and sustainability

Introduction to Design and Engineering

What is engineering?

Engineering is the field of practice, profession and art that relates to the development, acquisition and application of technical scientific and mathematical knowledge. It is about the understanding, design, development, invention, innovation and the use of materials, machines, structures, systems and processes for specific purposes (UNESCO 2025).

What is design?

A process that translates requirements into well-defined specifications for a product, system, or process. In this course, our focus will be exclusively on automotive product design.

How to Design? The Design Steps

A proper design follows a structured process. This process as shown in Figure 1.1 always starts from customer needs and ends with a final product. Each step is described briefly below.

Customer Requirements Analysis

This initial phase involves gathering and documenting all needs, expectations, and constraints from stakeholders. This involves interviews, market research, and feasibility studies to understand the problem space. The output is a comprehensive requirements document that serves as the foundation for all subsequent design work.

In vehicle design, customer requirements can be categorized as:

Practical & Performance: Cost, economy, weight, handling, speed, flexibility, comfort, durability, off-road capability, emissions, towing capacity, loading capacity, maneuverability, range, power, safety/crashworthiness.

Space & Capacity: Size, interior space, cargo volume, number of passengers.

Aesthetic & Customization: Image, trim level, colors, customizing potential, aftermarket component availability, brand identity.

User Experience: Security, noise/vibration/harshness (NVH), command-of-the-road seating, easy ingress/egress, sound.

Balancing Customer Desires with Manufacturing Reality

Automotive design must reconcile what customers desire with what manufacturers can realistically produce within regulatory boundaries. Achieving this balance is essential for creating viable, market-ready vehicles.

Manufacturing Limitations

Cost structures and budget constraints

Product portfolio strategy and brand positioning

Platform commonality and shared architectures

Derivative development capabilities

Production scale and volume requirements

Supply chain availability and logistics

Regulatory Requirements

Occupant protection standards (FMVSS, Euro NCAP)

Pedestrian safety protocols

Emission compliance (Euro 6, EPA standards)

Sustainable production mandates

Fuel economy regulations (CAFE, EU CO\(_2\) standards)

Successful vehicle development navigates these constraints while delivering compelling products. The best designs satisfy user expectations without exceeding practical manufacturing or regulatory boundaries.

Functional Requirements Development

The customer requirements are translated into specific, measurable technical specifications. This phase defines what the product must do (functional requirements) and how well it must perform (performance requirements). Requirements are prioritized and validated to ensure they are achievable within project constraints.

Requirements Translation Process:

Need Identification: What does the customer actually require?

Function Definition: How will the vehicle fulfill this need?

Performance Metrics: What measurable criteria define success?

Priority Ranking: Which requirements are critical vs. desirable?

For vehicles, functional requirements may include acceleration performance, braking distances, fuel consumption, handling characteristics, and crash safety ratings. Engineers must balance these factors with regulatory standards, ensuring compliance with industry requirements like Euro NCAP or EPA emissions regulations.

Example Translation:

Customer Need: “I need a safe family car”

Functional Requirements:

5-star safety rating capability

Minimum 5 seating positions

Child seat accommodation (ISOFIX/LATCH)

Advanced driver assistance systems (AEB, LKA)

Crash energy absorption structure

Conceptual Design

Engineers generate multiple design concepts through brainstorming and ideation sessions. Each concept is evaluated against the functional requirements using methods like Pugh matrices or weighted decision matrices (Hatamura 2006). The most promising concepts are selected for further development, often represented through sketches or basic CAD models.

During vehicle design, this step involves:

Selecting body style (sedan, SUV, hatchback, coupe, etc.)

Choosing drivetrain layout (front-wheel drive, rear-wheel drive, all-wheel drive)

Preliminary aerodynamic considerations

Material selection strategies for weight reduction while maintaining structural integrity

Platform architecture decisions

Powertrain type selection (ICE, hybrid, electric)

Preliminary Design

The selected concepts are developed into more detailed designs. Engineers create system architectures, perform initial calculations, and identify key components. Prototypes may be built to test critical functions. This phase often reveals necessary adjustments to both the design and requirements.

For vehicles, preliminary design includes:

Defining the powertrain specifications (internal combustion, hybrid, or fully electric)

Suspension geometry and kinematics design

Steering mechanisms and control systems

Basic electronic systems architecture

Vehicle packaging and space allocation

Preliminary structural design and load paths

Engineers may conduct wind tunnel testing and/or CFD simulations to optimize aerodynamics for fuel efficiency and performance. Initial crash simulation studies help validate safety concepts.

Detailed Design

Every aspect of the product is specified in precise detail. Complete 3D CAD models are developed, along with engineering drawings, material specifications, and manufacturing instructions. Simulations (FEA, CFD) are run to verify performance under expected operating conditions.

Vehicle detailed design includes the design of subsystems and components such as:

Chassis design and structural optimization

Powertrain integration and mounting systems

Electronic control unit (ECU) programming and calibration

Optimal tire sizes and wheel specifications

Suspension component design and tuning

Crash-impact zones through finite element analysis (FEA) simulations

Body panel design and manufacturing feasibility

Interior ergonomics and human factors engineering

Final Design and Testing

The completed design undergoes rigorous verification and validation testing. Prototypes are built and subjected to performance tests, environmental tests, and reliability tests. Test results may lead to final design refinements before production tooling begins.

For automobiles, this phase includes:

Crash tests (frontal, side, rollover, pedestrian impact)

Fuel efficiency validation and emissions certification

Long-term durability assessments and accelerated aging

Environmental testing (cold weather, extreme heat, high altitude, humidity)

NVH (noise, vibration, harshness) validation

Performance validation (acceleration, braking, handling)

Electromagnetic compatibility (EMC) testing

Prototypes are tested in different environmental conditions to verify real-world performance before mass production approval.

Production

The approved design moves into manufacturing. Production processes are optimized, quality control systems are implemented, and initial production runs are closely monitored. Feedback from early production often leads to minor refinements in both the product and manufacturing process.

In vehicle production:

Automated robotic assembly lines ensure consistency and precision

Quality control inspections identify defects before vehicles reach customers

Statistical process control monitors manufacturing variation

Endurance testing ensures mechanical reliability

Regulatory agencies certify safety and emissions compliance

Supply chain management ensures component quality and delivery

Continuous improvement processes optimize efficiency and quality

Product Life Cycle and the Circular Economy

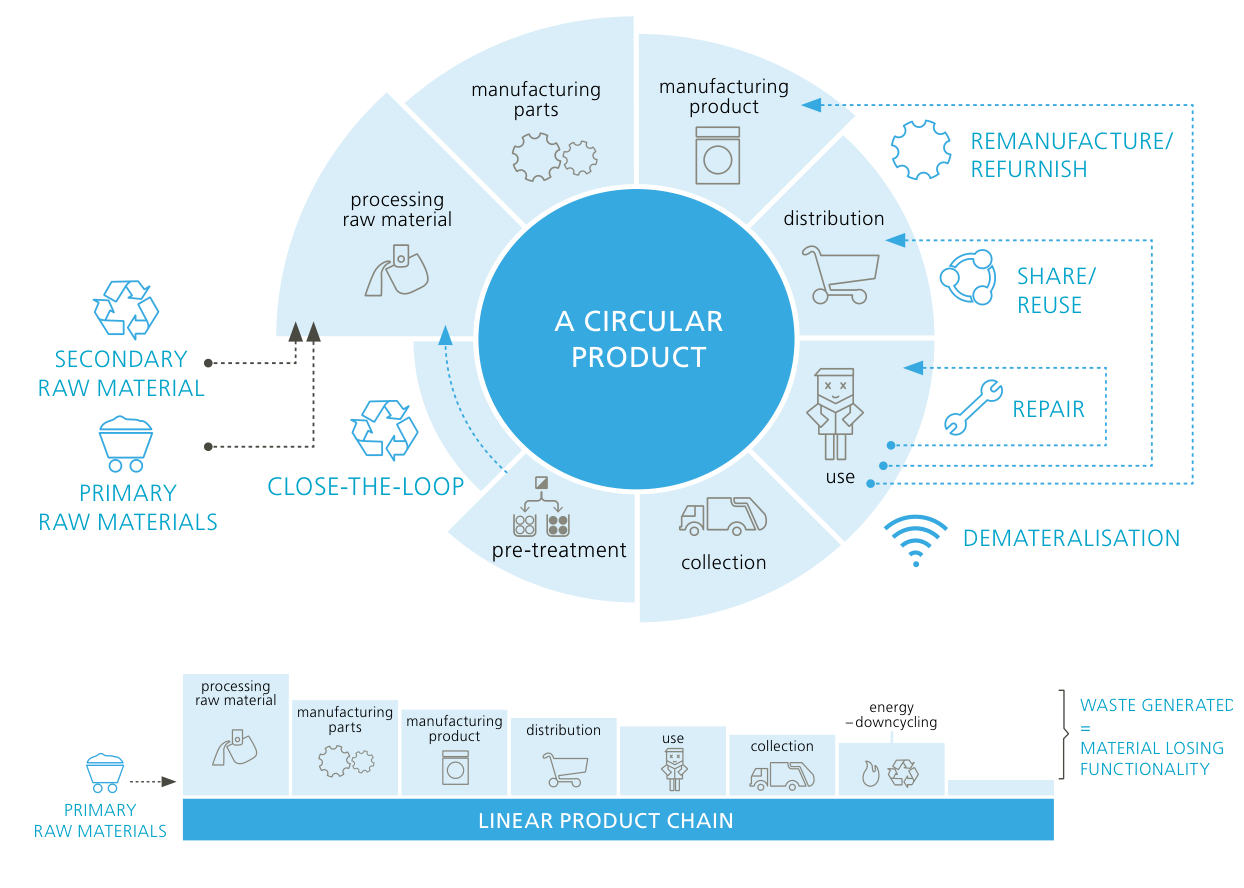

The linear design process depicted in Figure 1.1 focuses primarily on the design stage, but modern automotive design extends beyond this, considering the entire product life cycle (PLC). Traditionally, products followed a linear “take-make-dispose” model, leading to significant resource and energy waste. In contrast, the circular economy adopts a “cradle-to-grave-and-back-again” approach, prioritizing resource efficiency by designing products for longevity, reuse, and regeneration.

Understanding Product Life Cycle

The PLC, illustrated in Figure 1.2, describes the stages a product undergoes—from development and introduction to growth, maturity, and eventual decline or phase-out. Key phases include market research, design, production, marketing, and discontinuation. Businesses leverage PLC strategies to optimize pricing, promotion, and innovation while adapting to competition and technological shifts.

In manufacturing, particularly in the automotive industry, effective PLC management ensures cost efficiency and sustainability, with increasing emphasis on circular economy principles such as recycling and remanufacturing (Autoprotoway 2025).

Circular Economy Principles in Automotive Design

Materials are kept in circulation through strategies like remanufacturing, refurbishment, and recycling, minimizing environmental impact and creating closed-loop systems. The automotive industry exemplifies this shift through innovative design and business models:

Design for Circularity:

Vehicles engineered for disassembly with modular components

Design facilitates repair, upgrades, and repurposing

Material selection prioritizes recyclability and renewable sources

Standardized fasteners and connection methods for easy disassembly

Material Integration:

Integration of recycled materials (reclaimed plastics and metals)

Bio-based materials and sustainable alternatives

Reduced material variety to simplify recycling processes

Material passports for tracking component composition

End-of-Life Management:

Systematic dismantling to recover valuable parts and materials

Component remanufacturing and refurbishment programs

Material sorting and recycling optimization

Hazardous material safe disposal protocols

Business Model Innovation:

Car-sharing and mobility-as-a-service models

Leasing models that extend product utility

Component-as-a-service offerings

Take-back programs for end-of-life vehicles

Sustainability Impact

By embedding circular economy practices, the automotive sector not only reduces waste but also strengthens sustainability across the entire value chain—from raw material sourcing to end-of-life recovery. This approach:

Reduces demand for virgin materials and energy consumption

Minimizes waste generation and landfill burden

Creates new revenue streams through material recovery

Enhances brand reputation and regulatory compliance

Drives innovation in design and manufacturing processes

The integration of circular economy principles represents a fundamental shift in how the automotive industry approaches design, manufacturing, and business models, creating more sustainable and economically viable solutions for the future.

References

Autoprotoway. 2025. “Automotive Product Development: Stages, Case and Consideration.” https://autoprotoway.com/automotive-product-development/.

Hatamura, Yotaro. 2006. Decision-Making in Engineering Design: Theory and Practice. Springer. https://link.springer.com/book/10.1007/1-84628-261-6.

UNESCO. 2025. “Engineering | UNESCO.” https://www.unesco.org/en/basic-sciences-engineering/engineering.