Design for Safety: Crashworthiness

Design for Safety: Crashworthiness

Summary

Automotive safety includes active systems (accident prevention through ABS, ESC, ADAS) and passive systems (collision protection via crumple zones, safety cages, and restraints like airbags). Crashworthiness ensures structural energy absorption. Modern design employs CAE simulations to optimize safety while reducing physical tests. Safety evaluation uses standardized crash tests (frontal/side/rollover) with dummies measuring injury criteria, rated by scales like AIS. Programs such as Euro NCAP provide consumer ratings exceeding legal minimums.

Learning Objectives

Upon completion of this module, students will be able to:

Define the primary categories of automotive safety: active and passive safety.

Identify key technologies and structural elements associated with active and passive safety measures.

Explain the purpose and function of controlled collapse structures, safety cages, and crumple zones in vehicle crashworthiness.

Analyze how Computer-Aided Engineering (CAE) tools are integral to modern safe vehicle design and testing.

Evaluate the role of standardized crash tests and consumer rating programs like Euro NCAP in assessing vehicle safety performance.

Definitions of Safety and Crashworthiness

Automotive safety is broadly categorized into two main areas: active safety , which aims to avoid accidents, and passive safety , which focuses on protecting occupants and pedestrians in the event of an unavoidable collision. The technological understanding of vehicle safety has evolved over time, shifting from a simple concept of danger to one that incorporates calculable risk.

Crashworthiness specifically refers to the vehicle structure’s ability to adequately protect occupants during a collision. Its primary goal is to manage the impact kinetic energy, ensuring that a sufficient amount is absorbed by the vehicle’s structure. This absorption should result in acceptable levels of deceleration and minimal intrusion of deformed vehicle components into the passenger compartment. References used are (American Iron and Steel Institute 1998; Deb 2010; Europe (UNECE) 2025; Fisher 1977; National Highway Traffic Safety Administration (NHTSA) 2024; (NHTSA) 2025; Genta and Morello 2020; Mahmood and Paluszny 1981; Mallick 2010; Mom 2023; New Car Assessment Program (NCAP) and Euro NCAP, n.d.; Seiffert and Wech 2007).

Active Safety Measures

Active safety measures are designed to prevent accidents and enhance overall vehicle stability and control.

Electronic Control Systems: Modern vehicles extensively integrate electronic systems to assist drivers. These include:

Antilock Braking System (ABS) : Aids in controlled braking by preventing wheel lock-up.

Traction Control System (TCS) and Electronic Stability Control (ESC) : Enhance vehicle stability and roadholding by managing wheel slip and controlling yaw.

Adaptive Cruise Control (ACC) : Maintains a set distance from vehicles ahead.

Advanced Driver Assistance Systems (ADAS) : Such as forward collision warning systems, lane departure warning systems, automatic braking systems for reducing collision speed, and emergency stopping systems.

Ergonomic Design: The vehicle’s design is optimized to facilitate ease of control for the driver, minimizing fatigue and distraction. This involves clear visibility of instruments and controls, and ensuring all controls are easily accessible and intuitive to operate.

Steer-by-Wire: This radical technology replaces mechanical steering connections with electronic signals, offering precise control and contributing to advanced active safety, though it necessitates robust safety mechanisms.

Active Suspension Systems: These systems can adapt رشد road conditions and driving dynamics, further contributing to active safety by improving vehicle handling and stability.

Passive Safety Measures

Passive safety measures focus on protecting occupants and pedestrians from severe injury once an accident has occurred.

Controlled Collapse Structures: A fundamental principle is to design vehicle structures to collapse in a controlled and predictable manner during an impact. This allows the structure to absorb kinetic energy effectively. The aim is to minimize deformation of the cabin structure, safeguarding the occupants, and to dissipate collision energy within designated crushable zones over a short deformation length.

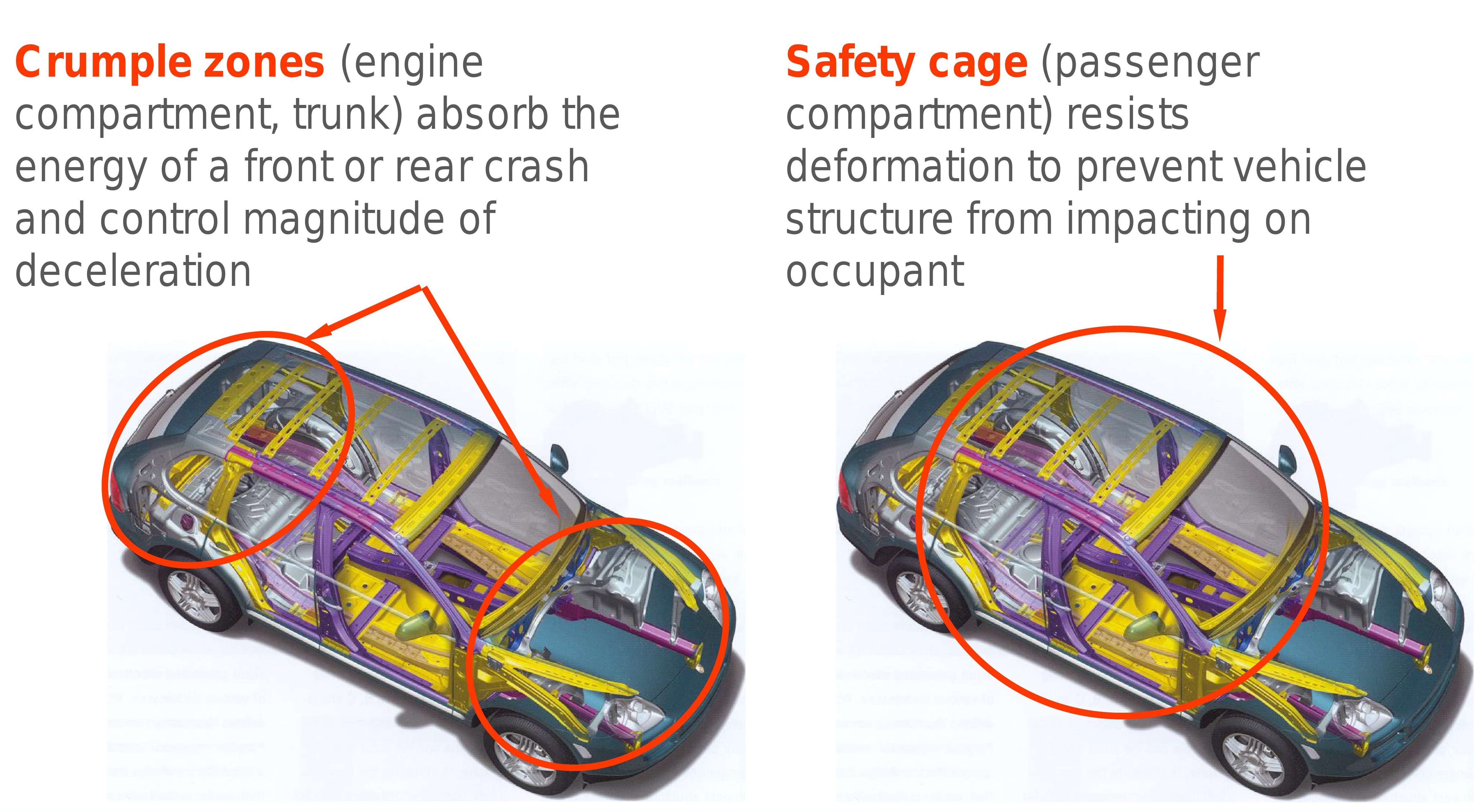

Safety Cage (Occupant Survival Shell): The passenger compartment, comprising elements like the A-pillar, B-pillar, roof rails, and door frame, is engineered to maintain its integrity and provide a protected space for occupants across various collision types, including side impacts and rollovers. This ensures sufficient space for restraint systems to function effectively.

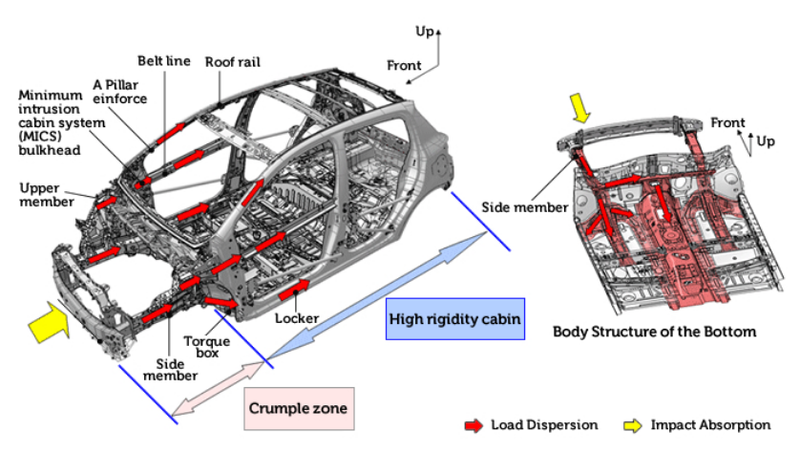

Crumple Zones: The front and rear sections of the vehicle are designed as primary crush zones, featuring structures that deform progressively, often in an accordion-like folding pattern, to absorb impact energy. These zones typically range from 500 to 900 mm in length for a 35 mph (56 kph) frontal impact. Rear side rails and wheel housings are also designed for progressive collapse in rear impacts. Longitudinal rails are critical to energy management as major force paths.

Structural Elements for Stiffness and Energy Channeling: Robust pillar/rail joint stiffness is crucial to resist body shell collapse and effectively channel crash energy away from the occupant compartment. The use of closed sections (e.g., box sections, tubular structures) significantly contributes to the overall torsional stiffness of the vehicle, which is vital for structural performance during impact.

Materials: Advanced materials like high-strength steels (including Ultra-High Strength Steels - UHSS), aluminum alloys , and fiber-reinforced composites are integral to crashworthiness design. They offer superior strength, energy absorption capabilities, and enable lightweighting, which can enhance safety by allowing for stiffer body structures to meet demanding offset crash requirements.

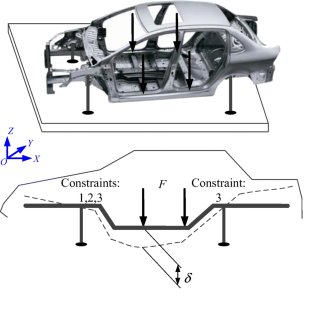

Safety cage and crumple zones.

Safety cage and crumple zones.  Controlled impact load path.

Controlled impact load path.

Occupant Restraint Systems:

Seat Belts : Three-point seat belts, often equipped with pretensioners, are considered the most effective restraint solution. Pretensioners are designed to quickly tension the belt upon impact, securing the occupant.

Airbags : Various types of airbags (front, side, curtain, and even hood/windshield for pedestrian protection) deploy rapidly to cushion occupants and prevent impacts with the vehicle’s interior. Advanced systems, such as ‘smart airbags’, can adapt their deployment velocity and intensity based on occupant size and weight data from sensors.

Collapsible Steering Column : Designed with telescopic or concertina-type elements to deform upon impact, preventing the steering wheel from intruding into the driver’s space and causing injury. Energy-absorbing elements within the column allow for rearward displacement of the steering wheel while maintaining the column’s axial and vertical position during a crash.

Head Restraints : Specifically designed to mitigate whiplash injuries during rear-end collisions.

Pedestrian Protection: Design efforts are increasingly focused on minimizing injury to pedestrians in collisions. This involves specific bumper configurations and the use of dedicated pedestrian impactor models for standardized testing. Utilizing lightweight materials and allowing for generous packaging space in the front structure can enhance pedestrian protection.

How to Design a Safe Vehicle

Designing a safe vehicle is a complex, iterative process rooted in a systems engineering approach.

Preliminary Design Focus: Crucial decisions regarding load paths and energy management strategies are made early in the design sequence, as alterations to major structural components become significantly more challenging and costly later in the development process. This initial phase involves establishing a clear philosophy for handling crash energy and packaging all major components and subsystems efficiently.

Structural Efficiency: An efficient structural design, characterized by effective load paths and distribution, is considered more critical for overall vehicle safety and efficiency than material selection alone. The overarching design goal is to achieve adequate strength and stiffness while minimizing vehicle mass.

Computer-Aided Engineering (CAE): Finite Element Method (FEM) and Multi-Body Simulation (MBS) are indispensable tools in modern vehicle design. They enable engineers to simulate complex movements, analyze internal loads, predict crash behavior, and optimize designs, leading to significant reductions in the need for costly physical prototype testing.

Simple Structural Surface (SSS) Method: During conceptual design, the SSS method offers a simplified, statics-based approach to rationalize load paths. It aids in visualizing load distribution and performing preliminary sizing of structural members.

Material Selection and Joining: The selection of materials is critical. High-strength steels and lightweight materials like aluminum and composites are chosen for their ability to meet stringent safety requirements while contributing to mass reduction. Adhesives are strategically used to enhance impact resistance in crush zones and improve the stiffness and strength of joints in the passenger compartment. Hybrid joining techniques, combining adhesive bonding with welding or riveting, are increasingly employed for superior stiffness and durability.

How to Test Safety

Vehicle safety is assessed through a combination of standardized physical tests and advanced computer simulations.

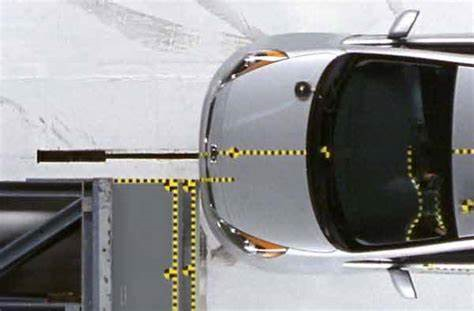

Standardized Crash Tests: Governments worldwide establish regulations and minimum performance levels for various crash scenarios. Key tests include:

- Frontal Impact : Typically involves head-on collisions with a rigid barrier (e.g., US FMVSS 208, NCAP at 30-35 mph / 48-56 kph). Offset deformable barrier tests (e.g., Euro NCAP at 40 mph / 64 kph) are also common. These tests measure deceleration, energy absorption, and passenger compartment intrusion.

Front impact test.

* **Side Impact** : Evaluates the integrity and energy absorption of the vehicle’s side structure, including door beams and the B-pillar, to limit intrusion into the occupant space.

Side impact test.

* **Rear Impact** : Focuses on minimizing passenger compartment intrusion from the rear and ensuring the integrity of the fuel system.

Rear impact test.

* **Rollover Resistance/Roof Crush** : Assesses the structural integrity of the roof in potential rollover scenarios.

Rollover test.

Physical Testing: While expensive and time-consuming, physical prototype crash testing remains essential for validating designs and complementing simulation results.

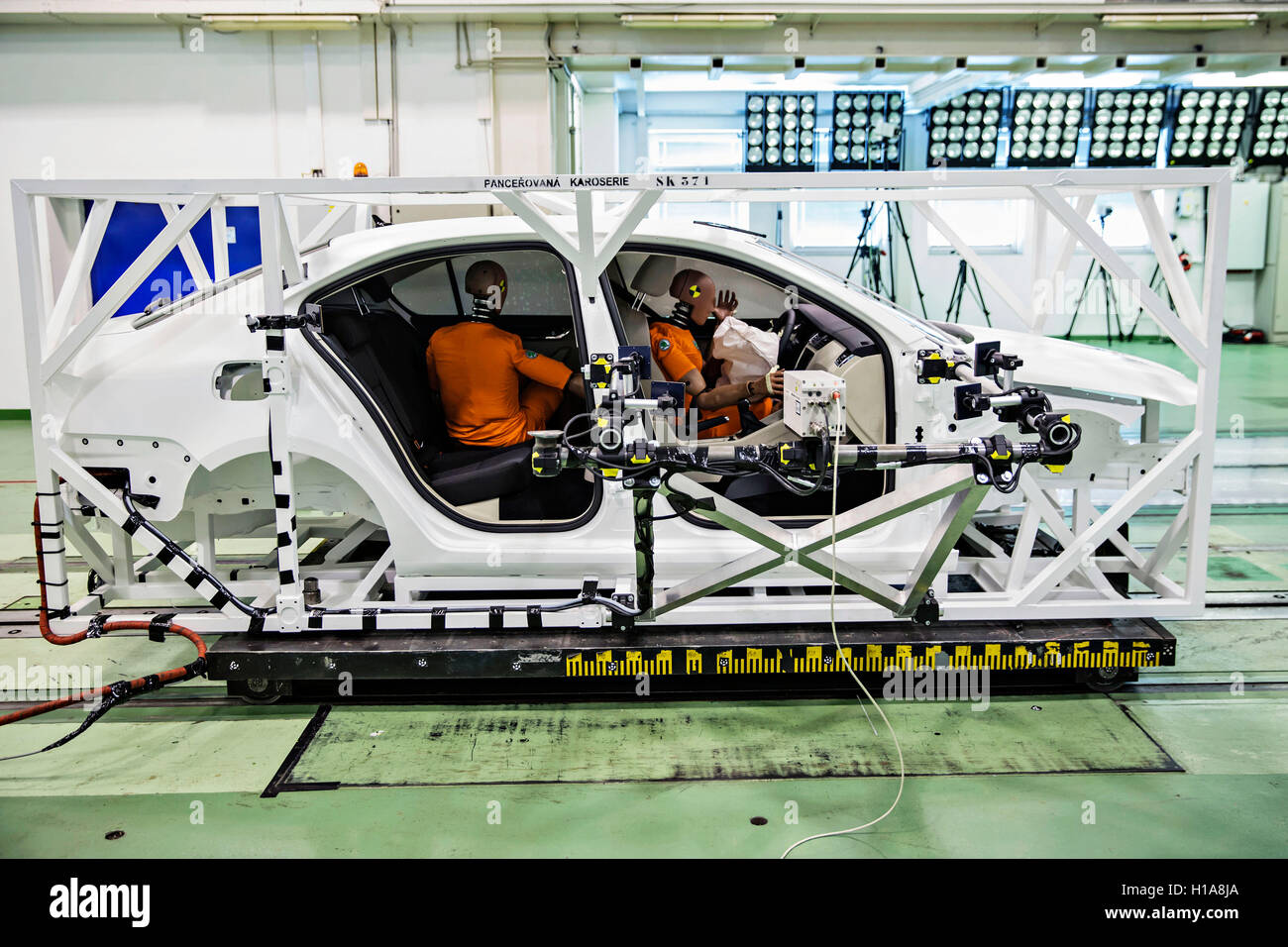

Sled Tests: Used in laboratories to simulate crash dynamics and evaluate the interaction between occupants and restraint systems.

Sled test.

- H Point Bending Test: This test assesses the bending strength and stiffness of the body structure by applying loads at the seating positions (H points) and measuring deflections. It simulates the way the body supports various subsystems and helps determine the load at which permanent deformation occurs, which is referred to as the measured bending strength (FS) [H point bending test].

H point bending test.

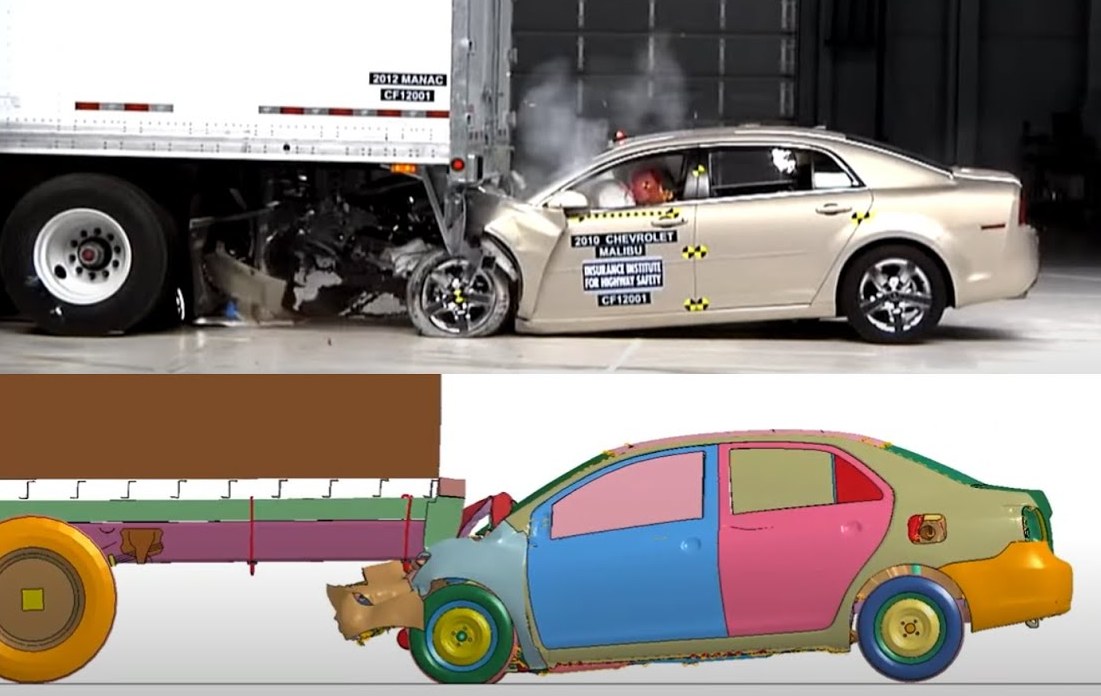

- Computer Simulation (CAE): Finite Element (FE) modeling and Lumped Parameter Modeling (LPM) are extensively used to predict vehicle performance under crash conditions. This significantly reduces development time and cost, optimizing designs before physical testing. LSDYNA is a frequently used explicit nonlinear dynamic analysis package for crash simulations. Simulations are rigorously validated against physical test data.

LS-DYNA car crash simulation.

Injuries

During automotive crash testing, sophisticated instrumented anthropomorphic test devices, commonly known as crash test dummies, are employed to measure a comprehensive array of injury parameters that correspond to potential human trauma in real-world accidents. These advanced measurement systems capture critical biomechanical data including the Head Injury Criterion (HIC), which quantifies the likelihood of head trauma based on acceleration patterns; chest-related parameters such as peak chest acceleration measured in gravitational units (chest g), chest compression values, the Thoracic Trauma Index (TTI), and the Viscous Criterion (VC) which collectively assess the risk of thoracic injuries including rib fractures and internal organ damage. Additionally, the measurement protocol encompasses lower extremity forces including pubic symphysis force and femur load to evaluate pelvic and leg injury potential, as well as the Combined Force and Moment Criterion for the neck region, which assesses cervical spine injury risk through complex loading patterns. These injury parameters serve as the foundation for vehicle safety assessment, with their indicative threshold values being continually revised and updated as medical understanding of injury mechanisms advances and as crash test methodologies become more sophisticated, ensuring that safety standards remain aligned with current knowledge of human injury tolerance and protection requirements.

Key Injury Parameters

The following table summarizes the primary injury parameters measured during crash testing:

| Primary Injury Parameters in Crash Testing Parameter | Description |

|---|---|

| HIC | Head Injury Criterion - quantifies likelihood of head trauma based on acceleration patterns |

| Chest g | Peak chest acceleration measured in gravitational units |

| Chest Compression | Measurement of thoracic deformation during impact |

| TTI | Thoracic Trauma Index - assessment of chest injury risk |

| VC | Viscous Criterion - evaluates internal organ damage potential |

| Pubic Symphysis Force | Force measurement at pelvic region |

| Femur Load | Loading forces on thigh bone |

| Combined Force and Moment Criterion | Neck injury assessment through complex loading patterns |

Injury Scoring and the Abbreviated Injury Scale

The Abbreviated Injury Scale (AIS) is a standardized anatomical scoring system that provides a comprehensive method for ranking and classifying the severity of injuries sustained in accidents. This internationally recognized scale serves as a critical tool in trauma assessment, medical research, and safety evaluation by assigning numerical values from 1 to 6 to different types of injuries based on their severity and potential threat to life. The AIS system enables healthcare professionals, researchers, and safety engineers to consistently quantify injury severity across different anatomical regions, facilitating meaningful comparisons in medical outcomes, treatment protocols, and safety system effectiveness. While crash test dummy measurements provide valuable biomechanical data on forces and accelerations experienced during impacts, the AIS ranking system translates these physical parameters into clinically relevant injury classifications that directly correspond to real-world medical consequences. This standardized approach allows for systematic evaluation of vehicle safety performance, medical resource allocation, and the development of injury prevention strategies by providing a common language for describing injury severity that bridges the gap between engineering measurements and medical practice.

AIS Classification System

The AIS scale categorizes injuries into six distinct severity levels, as detailed in Table 1.2.

| Abbreviated Injury Scale (AIS) Classification AIS Level | Severity | Injury Description |

|---|---|---|

| 1 | Minor | Abrasions, contusions, minor lacerations, or a concussion without loss of consciousness |

| 2 | Moderate | Undisplaced fractures, sprains, simple lacerations, or a concussion with brief loss of consciousness |

| 3 | Serious | Displaced fractures, joint dislocations, moderate head injury with prolonged loss of consciousness, or internal organ injury with minor bleeding |

| 4 | Severe | Multiple fractures, severe head injury with significant brain damage, or major internal organ injury with significant blood loss |

| 5 | Critical | Multiple open fractures, severe internal injuries with life-threatening complications, or severe burns |

| 6 | Maximum | Fatal injuries |

Test Ranking Systems

Consumer information programs, such as the New Car Assessment Program (NCAP) in the USA and Euro NCAP in Europe, provide safety ratings for new vehicles. These programs typically use a star rating system (1 to 5 stars) , with 5 stars representing the highest level of safety performance. For instance, a 5-star NCAP rating for a 35 mph (56 kph) frontal impact historically correlated to an average vehicle deceleration of 23g, while a 4-star rating correlated to 27g. These ratings also incorporate expert judgment on the overall vehicle behavior during the crash, including body deformation and airbag activation. Regulatory standards (e.g., FMVSS) define minimum performance levels, while NCAP programs aim to provide more stringent and publicized safety information to consumers.

Euro NCAP has developed a comprehensive five-star safety rating system designed to help consumers, families, and businesses compare vehicles more effectively and identify the safest options for their specific needs. The safety rating is determined through a series of rigorous vehicle tests conducted by Euro NCAP, which represent simplified but important real-life accident scenarios that could result in injury or death to car occupants or other road users (New Car Assessment Program (NCAP) and Euro NCAP, n.d.). The number of stars reflects not only how well a car performs in these standardized tests, but also considers the availability of safety equipment that manufacturers offer in each market. This dual consideration ensures that a high star rating indicates both excellent test performance and that critical safety equipment is readily accessible to all European consumers. The rating system continuously evolves as technology advances, with tests being updated regularly and new assessments added to reflect emerging crash avoidance and driver assistance technologies, making the latest rating always the most relevant for comparison purposes.

Star Rating Categories

The Euro NCAP star rating system provides clear guidance on safety performance levels, as summarized in Table 1.9.

Euro NCAP Star Rating System Summary

| Stars | Safety Performance Description |

|---|---|

| 5 | Overall excellent performance in crash protection and well equipped with state-of-the-art crash avoidance technology |

| 4 | Overall good performance in crash protection and prevention, but does not reach the highest standards in all key assessment areas |

| 3 | A vehicle that provides an average level of safety performance, offering a medium standard in safety |

| 2 | Nominal crash protection but below-average performance in one or more of the key assessment areas |

| 1 | Marginal crash protection and minimal crash avoidance technology beyond the legal requirements |

| 0 | Meeting type-approval standards so can legally be sold but lacking critical modern safety technology |

Important Considerations

The Euro NCAP rating system goes beyond minimum legal requirements, and not all new vehicles undergo Euro NCAP testing. A vehicle that merely meets legal standards would not be eligible for any stars. Additionally, ratings expire after six years due to the continuous evolution of safety standards and testing protocols. Some vehicles may have dual ratings: one based on standard equipment across all variants, and another based on optional safety packages that can enhance the overall safety rating.

References

American Iron and Steel Institute. 1998. “Ultra Light Steel Auto Body: Final Report.” Southfield, MI: American Iron; Steel Institute.

Deb, A. 2010. “Crashworthiness Design Issues for Lightweight Vehicles.” In Materials, Design and Manufacturing for Lightweight Vehicles , edited by P. K. Mallick, 332–55. Woodhead Publishing Limited; CRC Press LLC.

Europe (UNECE), United Nations Economic Commission for. 2025. “ECE Regulations for Vehicle Safety.” https://unece.org/transport/vehicle-regulations.

Fisher, J. W. 1977. Bridge Fatigue Guide-Design and Details. New York, New York: American Institute of Steel Construction.

Genta, Giancarlo, and Lorenzo Morello. 2020. The Automotive Chassis. Vol. 1 and 2. Springer Nature Switzerland AG.

Mahmood, H. F., and A. Paluszny. 1981. “Design of Thin Walled Columns for Crash Energy Management.” SAE Paper No. 811302.

Mallick, P. K. 2010. Materials, Design and Manufacturing for Lightweight Vehicles. Woodhead Publishing Limited; CRC Press LLC.

Mom, Gijs. 2023. The Evolution of Automotive Technology: A Handbook. SAE International.

National Highway Traffic Safety Administration (NHTSA). 2024. Federal Motor Vehicle Safety Standards and Regulations. U.S. Department of Transportation.

New Car Assessment Program (NCAP) and Euro NCAP. n.d. “New Car Assessment Program (NCAP) and Euro NCAP Information.”

(NHTSA), National Highway Traffic Safety Administration. 2025. “Federal Motor Vehicle Safety Standards (FMVSS).” https://www.nhtsa.gov/laws-regulations/fmvss.

Seiffert, Uwe, and Lutz Wech. 2007. Automotive Safety Handbook. Second. Warrendale, PA: SAE International.