Lecture 1: Making Economic Decisions and Costs Fundamentals

Introduction

Engineering economic analysis is about making rational decisions in situations involving costs, revenues, and benefits over time. This course provides tools to analyze and solve economic problems commonly faced by engineers.

Types of Decision Problems

Decision problems can be classified by complexity:

| Category | Description | Characteristics |

|---|---|---|

| Simple Problems | Routine choices with immediate or easily calculated consequences. | Require little time or effort to solve (e.g., paying cash vs. credit card, replacing a burned-out motor). |

| Intermediate Problems | Problems primarily economic in nature, requiring careful analysis and calculation. | Most suitable for engineering economic analysis (e.g., selecting equipment, determining component size). |

| Complex Problems | Issues combining economic, political, and humanistic elements. | Economic analysis solves the economic aspects (e.g., budgeting, plant location, infrastructure projects). |

Role of Engineering Economic Analysis (E.E.A.)

E.E.A. is critical because engineers design things that require spending money now, while benefits occur later. Use E.E.A. when:

- The problem is important enough to warrant serious effort

- It cannot be solved mentally; careful analysis is needed

- Significant economic aspects are crucial to the decision

E.E.A. helps answer:

- Is a project worthwhile?

- How should funding priorities be set?

- How can designs be optimized for cost-effectiveness?

The Rational Decision-Making Process

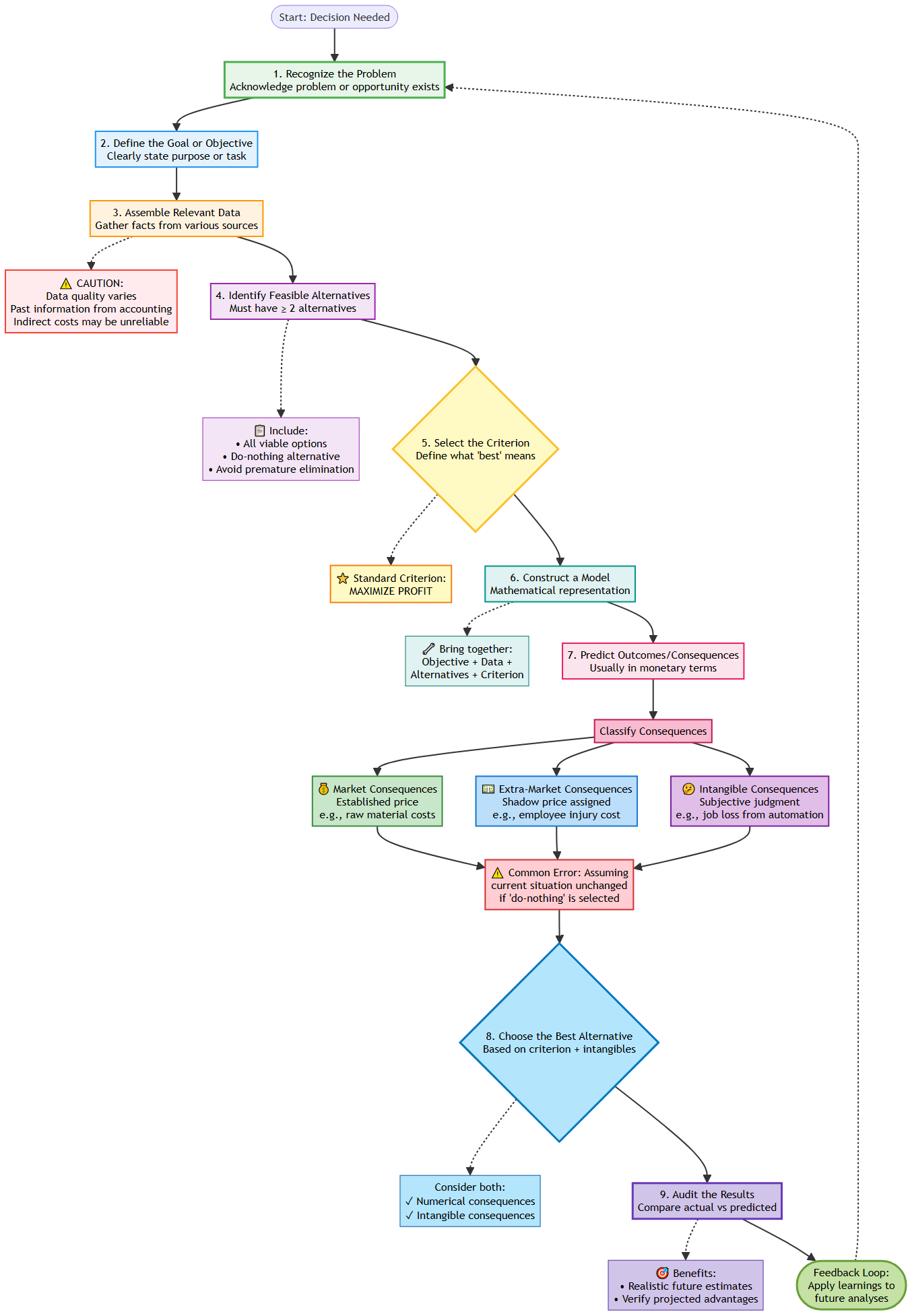

Rational decision making involves nine steps (see diagram below):

- Recognize the Problem: Acknowledge a problem or opportunity exists

- Define the Goal or Objective: State the purpose or task

- Assemble Relevant Data: Gather facts; beware of unreliable indirect costs

- Identify Feasible Alternatives: List all viable options, including “do-nothing”

- Select the Criterion: Define what “best” means (usually maximize profit)

- Construct a Model: Build a mathematical model of the situation

- Predict Outcomes: State consequences (market, extra-market, intangible)

- Choose the Best Alternative: Consider both numerical and intangible consequences

- Audit the Results: Compare actual results to predictions for future improvement

Selecting Economic Criteria

Based on maximizing profit, problems fall into three categories:

| Category | Situation Description | Economic Criterion |

|---|---|---|

| Neither Input nor Output Fixed | Both input and output are variable. | Maximize Profit (Value of Outputs – Cost of Inputs) |

| Fixed Input | Input resources are limited. | Maximize Benefits/Outputs |

| Fixed Output | Output objective is fixed. | Minimize Costs/Inputs |

Engineering Decisions for Current Costs

If all costs and benefits occur within a short period (less than a year), the time value of money is not relevant. Decisions should still use the three economic criteria above.

Ethical Dimensions in Decision Making

Engineers must consider ethics in all decisions. Ethics involves values, duty, and distinguishing right from wrong. Professional codes of conduct are essential.

Ethical issues can arise at every step:

- Problem Recognition: Ignoring safety problems

- Data Assembly: Using faulty data

- Prediction: Favoring one alternative with optimistic/pessimistic estimates

- Choice: Selecting inferior alternatives that compromise safety or add cost

- Audit: Hiding mistakes

Engineers must hold paramount the safety, health, and welfare of the public. Integrity is essential for long-term success. Ethical dilemmas often involve trade-offs between cost, quality, functionality, and safety.