Prosthetic Foot Project

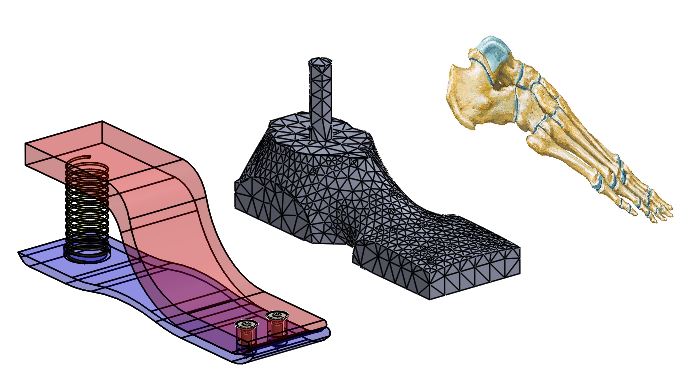

mechanical engineering, electric vehicles, prosthetic devices, vehicle safety, 3D printing, carbon fiber, AI in engineering, automotive engineering, crashworthiness, finite element analysis

Developing a Cost-Effective Prosthetic Foot for Below-Knee Amputees

Completed (2019) | Award: Innovation Award for 3D Printed Carbon Fiber Prosthetic Limb

Abstract

This research addresses the critical need for affordable prosthetic devices in developing regions where traditional commercial prosthetics are prohibitively expensive. We developed an optimized, low-cost transtibial energy storage and release (ESAR) prosthetic foot using topology optimization, 3D printing, and carbon fiber reinforcement. The resulting design achieves approximately 60% cost reduction compared to commercial alternatives while maintaining comparable mechanical performance and functionality.

Problem Statement

- Commercial prosthetic feet cost between $500-$5,000+, making them inaccessible for many amputees in developing regions

- Traditional manufacturing methods are expensive and time-consuming

- Limited customization options for individual patient needs

- Need for locally manufacturable solutions that reduce dependence on imported devices

Approach & Methodology

1. Design Optimization

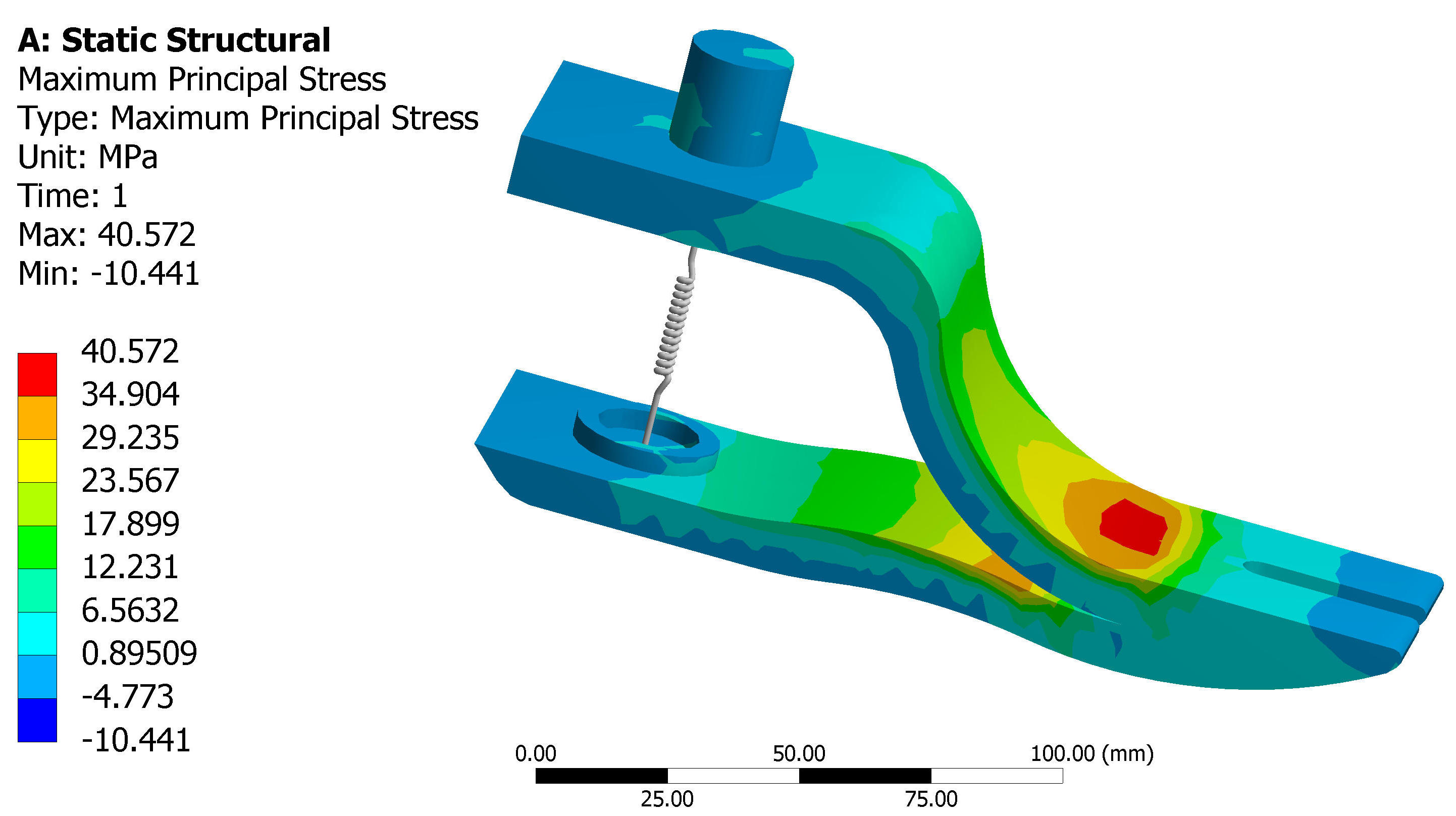

- Topology Optimization: Applied structural optimization techniques to identify optimal material distribution for energy storage and release during gait cycle

- Finite Element Analysis (FEA): Validated design performance under ISO 10328 loading conditions

- Design of Experiments (DOE): Systematic evaluation of design parameters to maximize performance-to-cost ratio

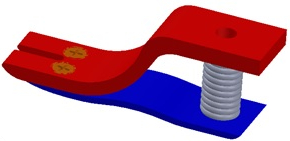

2. Advanced Manufacturing

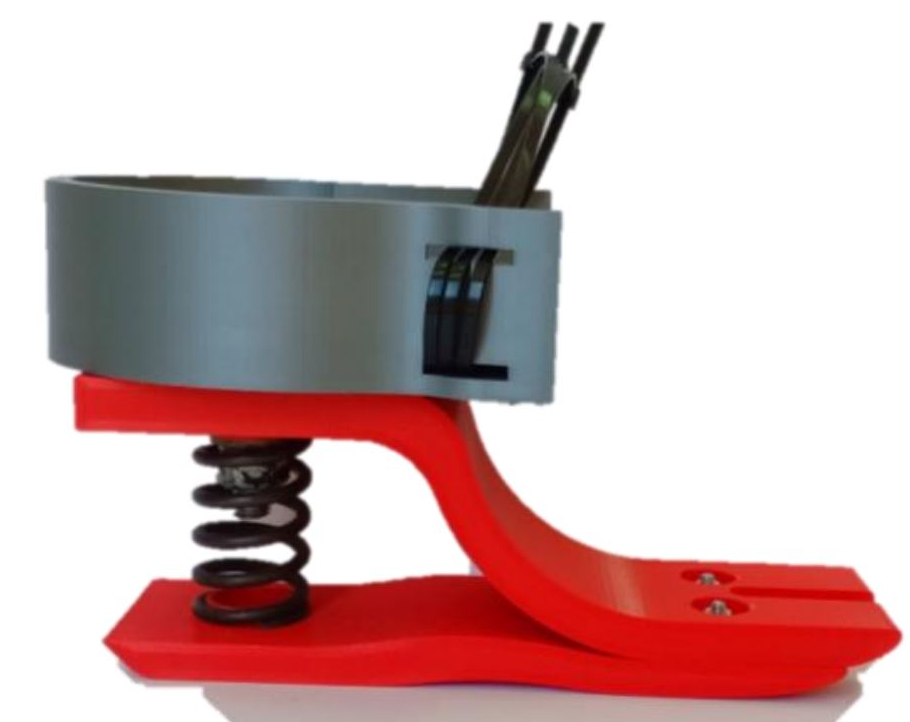

- 3D Printing: Utilized additive manufacturing (FDM/FFF) for rapid prototyping and production

- Carbon Fiber Reinforcement: Integrated continuous carbon fiber reinforcement in critical load-bearing regions

- Material Selection: Evaluated multiple polymer materials (PLA, ABS, PETG, Nylon) for optimal strength-to-weight ratio

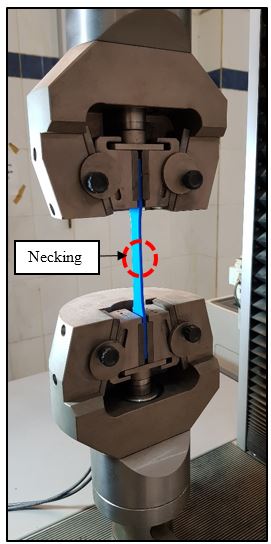

3. Testing & Validation

- Mechanical testing per ISO 10328 standards

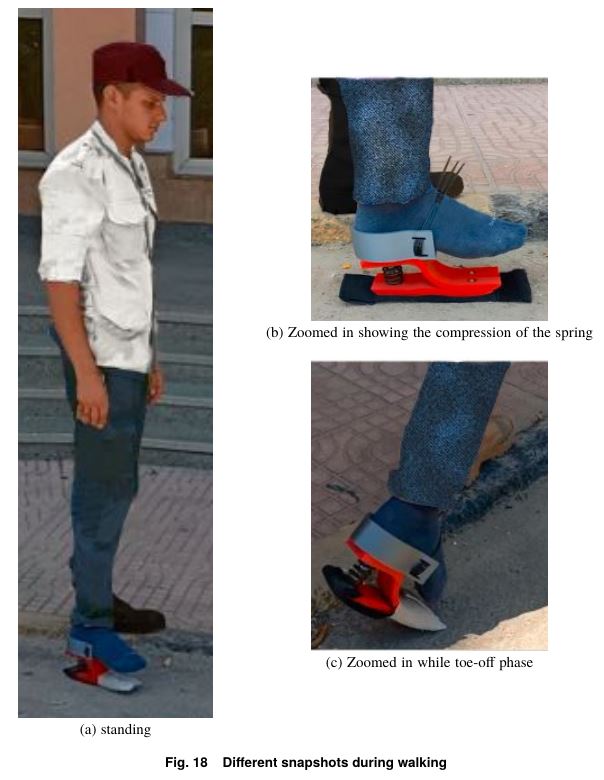

- Gait analysis and biomechanical evaluation

- Durability testing under cyclic loading

- User feedback and ergonomic assessment

Key Results & Achievements

Cost Reduction

- 60% lower cost than commercial alternatives

- Material costs: ~$50-100 vs. $500-5,000

- Locally manufacturable with accessible technology

Performance

- Meets ISO 10328 structural requirements

- Energy return comparable to mid-range commercial feet

- Lightweight design (comparable to commercial)

- Customizable for individual patient needs

Technical Specifications

| Parameter | Value |

|---|---|

| Weight | ~450-550g (depending on size) |

| Maximum Load | 100 kg body weight (ISO 10328 P4) |

| Energy Return | 65-75% (comparable to commercial ESARs) |

| Material | PLA/Nylon + Carbon Fiber |

| Manufacturing Time | 8-12 hours (3D printing) |

| Cost | ~$50-100 (materials only) |

Innovation & Impact

Technical Innovation

- First application of topology optimization + 3D printing + carbon fiber for prosthetic feet in regional context

- Developed design methodology that can be replicated for other prosthetic components

- Open-source design philosophy enabling local customization

Publications & Presentations

Kamel, Hisham, Omar Harraz, Khaled Azab, and Tamer Attia. “Developing an Optimized Low-Cost Transtibial Energy Storage and Release Prosthetic Foot Using Three-Dimensional Printing.” Journal of Engineering and Science in Medical Diagnostics and Therapy 3, no. 2 (2020). https://doi.org/10.1115/1.4046319

Kamel, Hisham, Omar Harraz, and Tamer Attia. “Developing a Cost-Effective and Functional Prosthetic Foot for below Knee Amputees Using Topology Optimization and 3D Printing.” Volume 3: Biomedical and Biotechnology Engineering, IMECE2019, American Society of Mechanical Engineers, November 2019. https://doi.org/10.1115/imece2019-10616

Research Team

- Prof. Hisham Kamel — Principal Investigator, Design Optimization & Manufacturing

- Dr. Omar Harraz — Biomechanics & Testing

- Dr. Khaled Azab — Material Science & Composite Integration

- Dr. Tamer Attia — Clinical Evaluation & User Testing

Future Directions

- Integration of smart sensors for gait monitoring

- Development of pediatric-sized prosthetics with growth accommodation

- Expansion to other prosthetic components (ankles, knees)

- Clinical trials for long-term durability assessment

- Open-source design repository for global collaboration

Gallery

CAD Design & Optimization

3D Printing & Manufacturing

Testing & Validation

Contact & Collaboration

Interested in collaboration, technology transfer, or clinical implementation? Contact hisham.kamel@mtc.edu.eg

Last updated: 2025

Social Impact